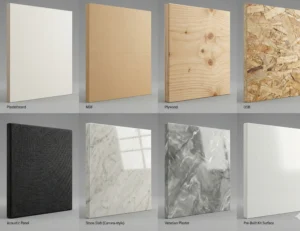

The best materials for a media wall depend on your budget, finish quality, and fire safety needs. UK builders use eight main options: plasterboard, MDF, plywood, OSB, acoustic panels, stone cladding, Venetian plaster, and pre-built kits.

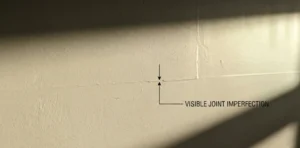

Professional builders prefer plasterboard because it creates seamless finishes. Wood Create, a UK building firm, states plasterboard beats MDF because MDF joints remain visible even after filling and sanding.

This guide covers every material option with costs, fire ratings, and UK building regulations. You’ll see what professionals actually use and why certain materials fail near fireplaces.

Material Comparison Overview

- Plasterboard – Professional Standard: Costs £8-£35 per sheet depending on fire rating. Euroclass A2-s1,d0 naturally fire-resistant. Requires plasterer (£150-£200) but creates seamless finish. Matches existing walls perfectly. 90% of UK professional installations use this.

- MDF – Budget DIY: Costs £25-£75 per sheet (fire-rated version pricier). Euroclass D-E standard, B-C fire-rated. No plasterer needed. Visible joints remain after painting. Strong screw holding throughout.

- Plywood – Moisture Areas: Costs £35-£65 per sheet. Better moisture resistance than MDF. Superior screw holding. Visible grain pattern. Euroclass D-E unless fire-treated.

- OSB – Cheapest Option: Costs £15-£25 per sheet. Rough textured appearance. Requires heavy prep. Euroclass D-E rating. Rarely used professionally.

- Acoustic Panels – Soundproofing: Costs £40-£120 per panel. Reduces noise 50-70%. Essential for shared walls. Home cinema installations.

- Stone/Quartz – Premium: Costs £80-£400 per square metre. Professional install essential. Heavy (requires reinforced frame). Luxury finish.

- Venetian Plaster – High-End: Costs £60-£150 per square metre installed. Skilled plasterer required. Unique polished finish.

- Pre-Built Kits – Fast Install: Costs £400-£1,400. Flat-pack or modular. 1-2 day installation. Limited customization.

MDF: Types and Specifications

Standard MDF:

- Density 600-800 kg/m³

- Smooth surface, no grain

- Euroclass D-E fire rating (fails near fireplaces)

- Screwfix: £28.99 per sheet

- Wickes: £28.99 per sheet

- Requires two primer coats before painting

Moisture-Resistant MDF:

- Green core identification

- 20-30% price premium (£38-£52 per sheet)

- Not waterproof, just moisture-resistant

- Use in rooms with condensation risk

Fire-Retardant MDF:

- Pink/red tint identification

- Euroclass B-C rating

- Hanson Plywood: £52.99 per sheet

- Medite Premier FR: £48.50 per sheet

- Required near electric fireplaces

Primed MDF:

- Factory primer applied

- Travis Perkins: £35.99 per sheet

- Ready for topcoat

- Saves prep time

When to Use MDF: Budget DIY where visible joints are acceptable. Strong fixing points needed for heavy shelves. Can paint yourself. Not near heat sources unless fire-rated.

Plasterboard: Standard and Fire-Rated

Standard Plasterboard 12.5mm:

- Gypsum core, paper facing

- Euroclass A2-s1,d0 (naturally fire-resistant)

- Wickes: £7.99 per sheet

- Screwfix: £9.49 per sheet

- Requires skim coat plaster

Fire-Rated Plasterboard (Pink Board):

- Glass fibre reinforcement

- 30-minute fire resistance (single layer)

- British Gypsum FireLine: £26.50 (Jewson)

- Knauf FirePanel: £23.99 (Screwfix)

- Gyproc FireLine: £24.99 (Travis Perkins)

Moisture-Resistant Plasterboard:

- Water-repellent additives

- £18-£28 per sheet

- Unnecessary for standard living rooms

- Use only in kitchens/bathrooms

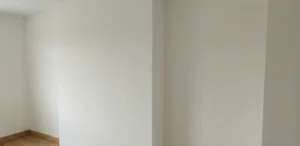

Why Professionals Choose Plasterboard: Wood Create states skim coat bridges joints completely. Creates monolithic surface matching existing walls. MDF seams remain visible under certain lighting. Professional reputation depends on flawless finishes.

For complete building instructions, check out how to build a media wall UK guide.

Plywood and OSB Alternatives

Structural Plywood:

- Cross-laminated layers

- Better screw holding than MDF

- Birch plywood: £42.99 per sheet (Jewson)

- Marine plywood: £58.99 per sheet (Travis Perkins)

- Visible grain requires prep for paint

- Euroclass D-E unless fire-treated

When Plywood Works: Moisture concerns (ground floor, external walls). Superior screw holding needed. Visible wood aesthetic desired. Structural backing for heavy TVs.

OSB (Oriented Strand Board):

- Compressed wood strands

- Wickes: £16.99 per sheet

- Screwfix: £18.50 per sheet

- Distinctive textured appearance

- Requires extensive prep

- Euroclass D-E rating

OSB Limitations: Rough surface needs heavy sanding. Edges swell if moisture exposed. Professional installations rarely use OSB for visible surfaces. Budget-only choice.

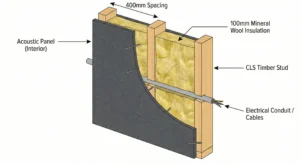

Acoustic Panels for Soundproofing

Fabric-Wrapped Acoustic Panels:

- 600mm x 600mm: £48.99 each

- 1200mm x 600mm: £89.99 each

- Mount to framework before surface material

- Reduces noise transmission 50-70%

When Soundproofing Matters: Shared walls with neighbours. Home cinema builds. TV sound bleeding to other rooms. Multi-occupancy buildings or flats.

Acoustic Plasterboard:

- Gyproc SoundBloc: £32.99 per sheet (Jewson)

- Replaces standard plasterboard

- Combined with 100mm insulation between studs

- Total acoustic treatment: £400-£650

Premium Finishes: Stone and Venetian Plaster

Natural Stone Cladding:

- Slate: £82.50 per m² (Stone Superstore)

- Marble: £125 per m² (Tile Giant)

- Limestone: £145 per m² (Natural Stone UK)

- Labour: £40-£80 per m² installation

- Requires reinforced framework (metal studs)

Engineered Quartz:

- Caesarstone: £280-£350 per m²

- Silestone: £320-£400 per m²

- Installation: £80-£120 per m²

- Extremely heavy (structural assessment needed)

Venetian Plaster:

- Materials: £15-£25 per m²

- Labour: £45-£125 per m²

- Total: £60-£150 per m² installed

- Skilled plasterer essential

Stone and quartz require metal stud frameworks. Weight exceeds 40kg per square metre. Professional installation non-negotiable.

Pre-Built Systems and Kits

Gypliner Wall System:

- British Gypsum pre-engineered metal system

- Complete kit: £340-£580 for 3m wall

- Travis Perkins and Jewson stock

- Faster than custom timber build

Flat-Pack Media Wall Kits:

- Pre-cut MDF/plywood components

- Homebase: £425-£899

- IKEA Besta adapted: £300-£650

- Specialist suppliers: £800-£1,400

- TV mount integrated

Modular Panels:

- Click-together systems

- Mount directly to wall (no framework)

- Dunelm: £380-£650

- Wayfair: £450-£950

- 1-2 day installation

Kits sacrifice customization for speed. Good for renters or temporary installs. Quality varies between manufacturers.

Framework: CLS Timber vs Metal Studs

CLS Timber (UK Standard):

- 50mm x 75mm nominal (38mm x 63mm finished)

- C16 grade: £8.99 per 2.4m length (Wickes)

- C24 grade: £11.50 per length (Travis Perkins)

- 400mm spacing = rigid feel

- 600mm spacing = building standard

- Kiln-dried below 20% moisture

Metal Studs:

- 70mm x 50mm typical

- British Gypsum GypFrame: £14.99 per 3m (Jewson)

- Knauf: £12.99 per 3m (Screwfix)

- Won’t warp or shrink

- Required for heavy stone/quartz

- Fire-resistant framework

Scaffold Board TV Backing: Some installers use scaffold boards behind TV zone. Provides solid 38mm backing across entire mounting area. Costs £18-£25 per 3.9m length. Eliminates need to hit specific studs.

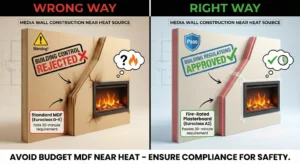

Fire Safety and Building Regulations

Building Regulations Approved Document B requires 30-minute fire resistance near electric fireplaces.

Fire Ratings Explained:

Euroclass A2-s1,d0 (Best for Residential): Standard and fire-rated plasterboard. Limited combustibility, minimal smoke. Meets Building Regulations without premium cost.

Euroclass B-C (Fire Retardant): Fire-retardant MDF, plywood, OSB. Chemical treatment applied. Costs 40-60% premium. Adequate when properly installed.

Euroclass D-E (Inadequate): Standard MDF, plywood, OSB. Not acceptable near fireplaces. Cannot meet Building Regulations for fire resistance.

System Performance: 12.5mm fire-rated plasterboard on timber studs at 600mm centres = 30-minute resistance. Double-layer or 15mm board = 60-minute resistance.

More fire safety details in our media wall with fireplace guide.

[Image needed: Fire-rated plasterboard (pink board) showing British Gypsum FireLine branding and Euroclass A2 rating label]

Cost Breakdown: Materials and Labour

Surface Materials (per 2440mm x 1220mm sheet):

- OSB: £15-£25

- Standard plasterboard: £8-£15

- Standard MDF: £25-£40

- Fire-rated plasterboard: £20-£35

- Plywood: £35-£65

- Fire-retardant MDF: £45-£75

Framework (per 3m wall):

- CLS timber C16 (8 studs): £72

- Metal studs (6 studs): £90

Labour Costs:

- Plasterer: £150-£200

- Joiner: £150-£250 per day

- Electrician (NICEIC): £300-£600

Complete DIY Costs:

- OSB budget: £300-£450

- MDF standard: £400-£600

- Plasterboard with plasterer: £500-£750

- Plywood: £550-£800

- Acoustic treatment: £400-£650 extra

Professional Installation:

- Standard builds: £4,800-£6,000

- Premium stone/quartz: £8,000-£15,000

Full cost comparisons in our media wall cost guide.

Electrical Work and Part P Compliance

All electrical work must comply with Part P Building Regulations.

Notifiable Work:

- New circuits from consumer unit

- Electric fireplace dedicated circuit

- Requires NICEIC/NAPIT registered electrician

Non-Notifiable:

- Adding sockets to existing circuits

- TV aerial connections

- LED lighting on existing circuit

BS 7671:2018 Requirements: Cable sizing for load. Safe zones (vertical/horizontal from outlets). Proper earthing. View BS 7671 wiring standards for details.

Typical Media Wall Electrical:

- 4-6 power outlets

- TV aerial/satellite

- LED strip lighting

- Electric fireplace circuit (if applicable)

Electrician costs £300-£600. Works best during framework stage before surface installed.

Common Installation Mistakes

Using Standard MDF Near Fireplaces: Euroclass D-E rating fails Building Control. Use fire-retardant MDF (£48-£75) or fire-rated plasterboard (£23-£35).

Forgetting Plasterer Costs: Plasterboard needs professional finish (£150-£200). Budget accordingly or choose MDF.

Wrong Stud Spacing: 600mm feels bouncy. 400mm spacing costs £40-£60 more but eliminates flex. Professionals always use 400mm.

Skipping Vapour Barrier: Media walls against external walls need DPC membrane (£25-£40). Prevents condensation and timber rot.

Inadequate Framework for Stone: Stone weighs 30-50kg per square metre. Needs metal studs or doubled timber. Standard CLS inadequate.

Material Selection Decision Guide

Choose Fire-Rated Plasterboard If: Installing electric fireplace. Want seamless professional finish. Can hire plasterer £150-£200. Meets Building Regulations. Industry standard choice.

Choose Standard MDF If: Tight budget, DIY installation. Accept visible joints. No fireplace present. Strong fixing points needed. Paint yourself.

Choose Fire-Retardant MDF If: Prefer MDF but have fireplace. Accept 40-60% cost premium. Still want DIY-friendly material.

Choose Plywood If: Moisture concerns (ground floor, external walls). Superior screw holding needed. Visible wood grain desired.

Choose OSB If: Absolute minimum budget. Industrial aesthetic acceptable. Hidden behind paneling. Temporary installation.

Choose Acoustic Panels If: Shared walls with neighbours. Home cinema build. Soundproofing priority. Multi-occupancy building.

Choose Stone/Quartz If: Budget allows £2,000+ materials. Luxury project. Professional installation guaranteed. Feature wall statement.

Choose Pre-Built Kits If: Limited DIY skills. Want fastest installation. Rental property (removable). Standard sizes fit.

Where to Buy Materials

Budget Suppliers: Wickes – competitive pricing, limited specialist products. OSB £16.99, MDF £28.99, CLS timber £8.99.

Mid-Range: Screwfix – Knauf FirePanel £23.99, good product range. Travis Perkins – similar pricing, broader timber selection.

Trade/Professional: Jewson – British Gypsum FireLine £26.50, specialist products. Buildbase – trade pricing, acoustic options well-stocked.

Specialist: Hanson Plywood – fire-rated MDF and specialist boards. Materials Market – Gypliner systems. Stone Superstore – cladding. Soundproof Store – acoustic treatments.

Trade accounts offer 10-15% discount at most suppliers.

Professional vs DIY Recommendations

Professional Standard Specification: 12.5mm fire-rated plasterboard (British Gypsum FireLine or Knauf FirePanel). CLS timber C16 at 400mm spacing. Skim coat by qualified plasterer. NICEIC electrician. Building Control notification for fireplaces.

Why Professionals Use This: Wood Create states plasterboard creates seamless finishes meeting client expectations. Skim coat eliminates all joints. Matches existing walls perfectly. Professional reputation depends on flawless results.

When Professionals Use MDF: Client specifically requests for cost savings. Decorative paneling covers surface. Budget rental properties. Quick flip renovations.

DIY Preferences: MDF popular for DIY (no plasterer needed). Accept visible joints for £150-£200 savings. Confident DIYers choose plasterboard but hire plasterer for finishing only.

Final Thoughts

Eight material options exist with costs from £300-£15,000 depending on choice and installation. Professional UK builders use 12.5mm fire-rated plasterboard for 90% of residential projects creating seamless finishes through skim coat application. Budget DIY builds use MDF accepting visible joints saving plasterer costs. Fire safety near electric fireplaces requires fire-rated materials meeting 30-minute Building Regulations minimum with proper certification.

Frequently Asked Questions

Do I need Building Control approval to build a media wall?

No for standard media walls without electrical work. Yes if installing electric fireplace requiring new circuit or work near fire-rated walls. Electrical work needs Part P compliance regardless.

Can I skim plasterboard myself or must I hire a plasterer?

You can attempt it but poor technique shows every imperfection under paint. YouTube tutorials help but first-time results rarely match professionals. Practice on garage wall first or hire plasterer for £150-£200.

How long after plastering can I paint a media wall?

Wait minimum 7-10 days for plaster to fully dry. Rushing causes paint to bubble and peel. Use mist coat (10:1 water:paint ratio) first then wait 24 hours before two full coats.

What’s the actual difference between Knauf and British Gypsum fire-rated plasterboard?

Performance identical – both achieve 30-minute Euroclass A2 rating. British Gypsum FireLine costs £26.50 at Jewson, Knauf FirePanel costs £23.99 at Screwfix. Choose based on price and availability not performance.

Do I really need a vapour barrier behind a media wall?

Only if against external wall on ground floor or in homes with previous damp history. Internal walls in modern homes don’t need it. DPC membrane costs £25-£40 preventing timber rot from condensation.

How do you hide cables inside a media wall properly?

Route cables through timber studs during framework stage before surface material installed. Drill 25mm holes through stud centres. Use rubber grommets protecting cables from sharp edges. Plan outlet positions before building framework not after.

Can you relocate or remove a media wall later without damaging the room?

Timber-framed media walls fixed to floor, wall, and ceiling leave fixing holes requiring filler and paint. Pre-built modular kits easier to remove. Plasterboard media walls require complete demolition – not relocatable. Plan as permanent installation.